Geared Automatic Tapping

2nd Generation – Fast tapping machines, can produce components up-to 25 pcs per minute.

Features under this category

- Rigid Construction Fabricated base Stress relieved and duly scrapped to achieve desired accuracies as per IS standards.

- Tapping cycle (Tap forward cycle – dwell – Tap reverse cycle).

- Spindle drive through v-stepped pulley.

- Inbuilt job counter & tool change counters.

- Inbuilt clamp / declamp cycle for tooling automation.

- 3 Phase, 50Hz, TEFC, F class insulation, Induction Motor with temperature sensors with its controller.

- Automatic tapping is driven by gear pair which provides standard pitch, accurate thread and consistent quality level for tapping.

- Easy replacement of gear pair for different pitches, fitted externally.

- Does not exert extra pressure on component, due to thrust compensation clutch on quill.

- There is no reverse cut or pulling force on component during return stroke of tapping.

- Safety mechanism prevents breakage in case of spindle overload.

- Machines can be equipped with Multi-Spindle Heads for mass production.

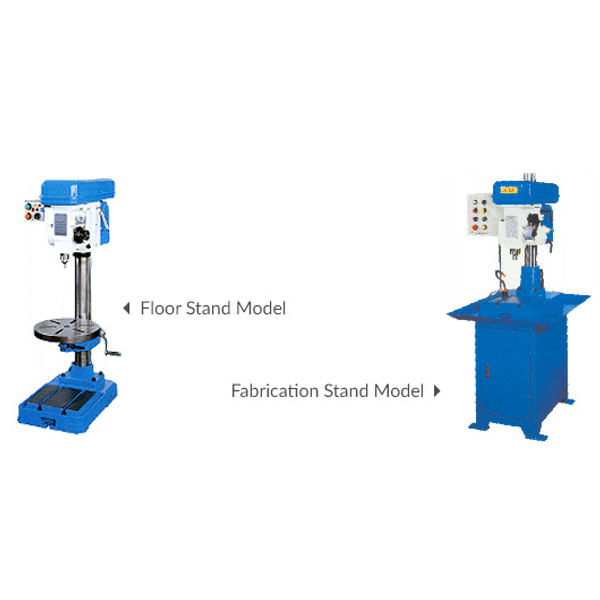

Geared Automatic Tapping Machine

|

| Model |

GT110 |

GT80 |

GT50 |

| Maximum Tapping Capacity (S45C) |

M35 |

M16 |

M8 |

| Spindle Taper |

MT4 |

MT3 |

JT2 |

| Spindle Travel |

60mm |

60mm |

40mm |

| Spindle Speed (Optional) |

85-170-240rpm |

155-285-515rpm |

420-760-1340rpm |

| Throat (Column to Spindle Centre) |

260mm |

230mm |

180mm |

| Table Area |

600X400mm |

500X400mm |

400X300mm |

| Column Diameter |

Ø 115mm |

Ø 102mm |

Ø 80mm |

| Distance from Spindle To Table |

100-700mm |

100-700mm |

100-700mm |

| Motor HP |

3HP |

2HP |

1HP |

| Overall Height |

2100mm |

2100mm |

1600mm |